Assembly and Branch Hoses are used to connect multiple hoses with a common connector such as in engines to supply oil, fuel, gas or coolant. These are manufactured from premium quality raw material that provides ability to withstand wide temperature range from -40°C to 140°C.

Rubber Hoses & Assemblies

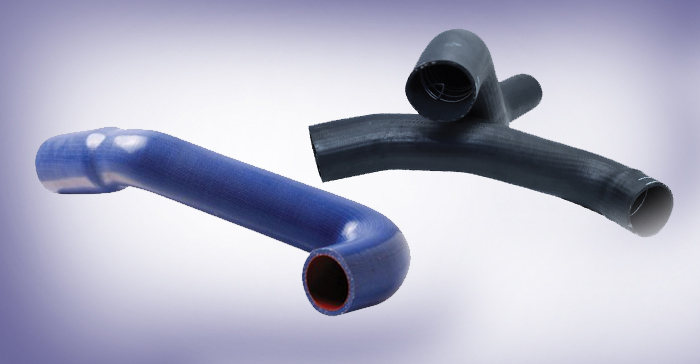

Branch Hoses

Co-Extruded Hoses

Co-Extruded Hoses can encounter demanding conditions such as high temperature and weathering. The CO- extrusion is being basically done for the polymers of the high density to meet the tier IV or Euro 6 norms.

We possess the state of the art facility for the co-extrusion of the 2 polymers on the fully automated extrusion line. The machine is capable of co-extruding the following polymer combination for the inner layer with different hose construction patterns.

- FPM and AEM

- FPM / FVMQ and VMQ

The equipment is used in the production of rubber profiles, multi-ply automotive hoses as turbocharger, fuel, power steering, fuel, rubber lined rolls for printing, and hoses based on silicone rubber. The Extruder Dia ranging from 12mm dia to 50mm screws has the automoized PLC controls for the controlled wall thickness variations within +/-0.2 mm

Radiator, Heater & CAC Hoses

Produced from EPDM Terpolymers to withstand Temperatures up to 150°C. The Reinforcement can very depending on temperature and pressure requirements. The Reinforcement can be RAYON, POLYESTER or ARAMID. Commonly used in Radiator and Engine applications.

CAC Hoses

Designed and engineered to provide a connection between engine mounted charge air system components

Generally EPDM Rubber is used for normal and moderate high temperature application.

The AEM and the EPDM hoses with the meta aramid reinforcement are used for the cold side of the intercooler. The EPDM can work till 150 degrees C and the various other polymers with same reinforcement are used for the Intercooler hoses upto 175 degrees Celcius

Silicone Hoses

Suitable for cooling systems, charge air systems and induction systems. With its’ temperature range stability, flexibility, longevity, thermal, and electrical insulation properties, silicon polymers are a modern miracle of engineering material science.Manufactured from premium quality raw material, silicone hoses are used for high performance applications such as turbochargers. These hoses can withstand wide temperatures ranging from -40°C to 200°C.

Fuel & Vacuum Hoses

Multilayer Hoses with an Impermeable Inner Layer of Fluoroelastomer with layers of EPICHLOROHYDRIN, subsequently Braided with PET / Aramid covered with a Heat, Ozone resistant layer. These are normaly low diameter hoses that withstand Max Pressure of 60 MPa.

Quality Policy

From the start, our commitment has been to provide the customer with the optimum solution by offering quality products and services. Our in house knowledge in the field of hose industry coupled with decades of experience has enabled us to reach and eliminate the customer’s problem and minimize cost overhead in the long run.

COMMITTED TO THE PRODUCTION AND IMPROVE OUR BRAND STRENGTH

- Strength

- Technology

-Fastest turnaround times in the industry

-Customized Product Design

-Advanced Equipment

-Strict control to ensure installation accuracy

We have the latest equipment and machines to manufacture and produce OEM standard and zero defect products that are best in fit, finish and performace.

Invictus Autotek Private Limited integrated manufacturer and assembler of Fluid Transmission Products and rubber molded parts covering all spectrums that include flexible high-pressure assemblies, metal tubular assemblies, and low-pressure hose assemblies and suspension items.

The organization was established as a small-scale enterprise in Faridabad, India. Today it has a widespread setup with over 20 facilities across India managed by the parent company.