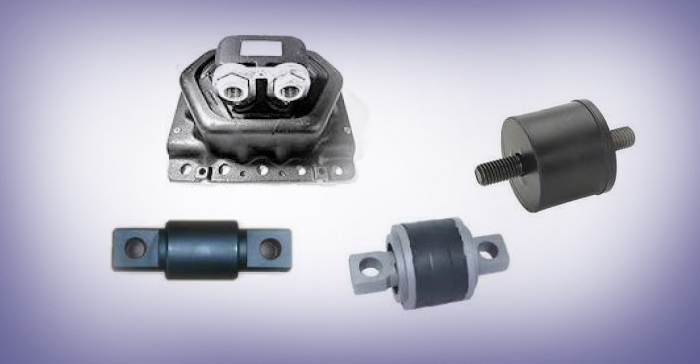

Rubber to Metal bonded parts and Suspension items

Rubber To Metal Bonded Part is a means by which rubber is mechanically bonded to a metal insert during the molding process. To begin the bonding process, the inserts are first prepped for production using a degreasing system to rid the parts of any contaminants before the adhesive is applied. Next, the heat activated adhesive is applied to the inserts using a technique similar to spray painting. Once the metals are prepared, they are ready for production.

The inserts are then physically placed, one at a time, into each cavity of the mold. For inserts on the top of a part, special magnets are incorporated into the mold to hold them in place while the mold is being loaded. Also, for inserts being encapsulated into the rubber, special chaplet pins are incorporated into the mold to suspend the insert in the mold & allow the rubber to flow around the metal.

- Engine & Hydro Mounts

- Rubber to Metal Bonded

- Suspension Bushes

- Buffer & Pads

Quality Policy

From the start, our commitment has been to provide the customer with the optimum solution by offering quality products and services. Our in house knowledge in the field of hose industry coupled with decades of experience has enabled us to reach and eliminate the customer’s problem and minimize cost overhead in the long run.

COMMITTED TO THE PRODUCTION AND IMPROVE OUR BRAND STRENGTH

- Strength

- Technology

-Fastest turnaround times in the industry

-Customized Product Design

-Advanced Equipment

-Strict control to ensure installation accuracy

We have the latest equipment and machines to manufacture and produce OEM standard and zero defect products that are best in fit, finish and performace.

Invictus Autotek Private Limited integrated manufacturer and assembler of Fluid Transmission Products and rubber molded parts covering all spectrums that include flexible high-pressure assemblies, metal tubular assemblies, and low-pressure hose assemblies and suspension items.

The organization was established as a small-scale enterprise in Faridabad, India. Today it has a widespread setup with over 20 facilities across India managed by the parent company.